Injection Mold Manufacturer

Choosing the Right Injection Mold

Manufacturer: A Complete Guide

In the fast-paced world of manufacturing, partnering with a reliable injection

mold manufacturer is vital to achieving consistent product quality, reduced

time to market, and cost-effective production. Whether you're launching a new

product or scaling an existing one, your mold manufacturer plays a critical

role in turning designs into precision-engineered plastic components.

In this blog, we explore what an injection mold manufacturer does, the

key services they offer, essential specifications, and how to choose the right

partner for your business. We also include FAQs to answer the most common

questions companies have when sourcing molds.

What Does an Injection Mold

Manufacturer Do?

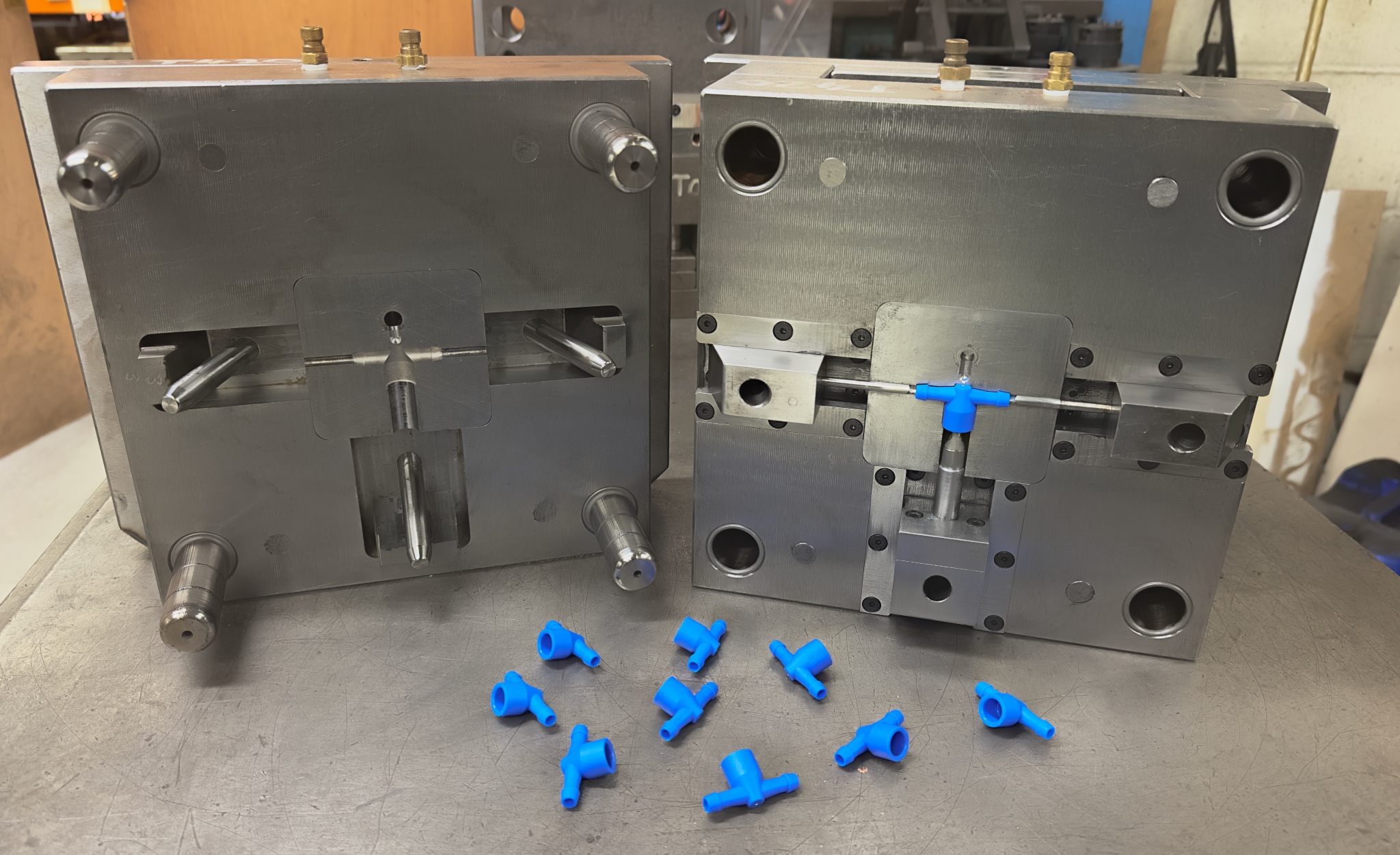

An injection mold manufacturer specializes in designing,

engineering, and fabricating high-precision tooling (molds) used in the plastic

injection moulding process. These molds are custom-built to produce plastic

parts by injecting molten polymer into a cavity, which then cools and

solidifies into the desired shape.

Injection mold manufacturers work closely with product designers and

engineers to develop robust tooling solutions that ensure high-volume,

defect-free production.

Key Services Offered by Injection Mold

Manufacturers

A reputable injection mold manufacturer typically provides a wide range

of services, including:

1. Mold Design & Engineering

Advanced CAD/CAM software is used to design the mold based on the product

geometry, material requirements, and production goals.

2. Tooling Fabrication

Precision machining techniques such as CNC milling, EDM (Electrical

Discharge Machining), and grinding are used to manufacture mold components.

3. Mold Testing & Validation

Molds are tested through trial runs to ensure proper function, accurate

dimensions, and absence of defects like short shots or flashing.

4. Maintenance & Repairs

Mold manufacturers also offer ongoing support for tool maintenance,

repairs, and refurbishing to extend mold lifespan.

5. Prototype & Production Tooling

Depending on project needs, manufacturers can create both rapid prototype

molds (usually aluminum) and durable production molds (typically hardened

steel).

Technical Specifications of a

High-Quality Injection Mold Manufacturer

Below is a list of key specifications and capabilities to look for when

choosing an injection mold manufacturer:

|

Specification |

Typical Values or Description |

|

Mold Materials |

P20, H13, S136 steel, aluminum (for prototype) |

|

Mold Life |

100,000 to over 1 million cycles |

|

Max Mold Size |

Up to 1500mm x 1000mm (varies by shop capability) |

|

Tolerance Precision |

±0.01 mm to ±0.05 mm |

|

Supported Polymers |

ABS, PP, PC, PA, POM, TPE, PEEK, etc. |

|

Number of Cavities |

Single, Multi-cavity (2, 4, 8, 16, 32+) |

|

Surface Finish Options |

SPI (A1 to D3), EDM texture, VDI, custom grain finishes |

|

CAD Software Used |

SolidWorks, NX, CATIA, AutoCAD, Moldflow |

|

Certifications |

ISO 9001, ISO 13485, IATF 16949 (for automotive/medical) |

Benefits of Partnering with a

Professional Mold Manufacturer

Partnering with the right mold manufacturer provides long-term value and

operational efficiency. Here's why it matters:

1. Precision & Consistency

Expert manufacturers ensure your molds produce accurate and repeatable

parts over thousands—or even millions—of cycles.

2. Reduced Downtime

Quality tooling reduces the risk of production stoppages due to flash,

warping, or ejection issues.

3. Cost Efficiency

Well-designed molds decrease scrap rates and reduce material wastage,

directly impacting your bottom line.

4. Faster Time to Market

Skilled manufacturers can accelerate design iterations, prototyping, and

production tooling to help you launch products faster.

5. Expert Support

From design to post-production, experienced manufacturers provide

guidance on part geometry, material selection, and mold design optimization.

Industries Served by Injection Mold

Manufacturers

Injection mold manufacturers serve a wide variety of sectors that demand

high-quality plastic parts:

- Automotive – Lighting

housings, air ducts, dashboard parts, under-hood components.

- Medical – Surgical

tools, housings for diagnostic devices, syringes, implantable components.

- Consumer Goods – Kitchen

appliances, packaging caps, electronic enclosures, toys.

- Aerospace – Lightweight

structural plastic components and housings.

- Industrial

Equipment – Electrical enclosures, machine handles, sensor housings.

Their expertise allows them to meet regulatory requirements, such as FDA

or ISO compliance, depending on industry needs.

How to Choose the Right Injection Mold

Manufacturer

When evaluating potential injection mold manufacturers, consider the

following criteria:

1. Experience and Industry Expertise

Choose a manufacturer with a proven track record in your industry or with

similar product types.

2. In-House Capabilities

A full-service facility with in-house design, machining, and testing

ensures better control over timelines and quality.

3. Tooling Quality and Materials

Verify the types of steel and processes used for mold fabrication.

High-grade materials increase tool life and reduce maintenance needs.

4. Customer Support &

Communication

Transparent, responsive communication is essential for project success,

especially during design iterations.

5. After-Sales Services

Look for manufacturers offering mold maintenance, repair, and

modification support post-delivery.

FAQs About Injection Mold

Manufacturers

Q1. What is the typical lead time for

mold manufacturing?

A: It depends on complexity. Simple molds can be ready in 3–6 weeks, while

complex or multi-cavity tools may take 8–12 weeks.

Q2. How long does a mold last?

A: Mold life varies based on material and usage. Aluminum molds may last

10,000–50,000 cycles, while hardened steel molds can exceed 1 million cycles.

Q3. Can I request modifications to an

existing mold?

A: Yes, most manufacturers offer mold modification services if the part

design changes or new features are added.

Q4. Is it better to manufacture molds

domestically or overseas?

A: Domestic manufacturing may offer faster communication and better quality

control, while overseas options (e.g., in China) can be more cost-effective but

require strong vendor management.

Q5. What file formats do manufacturers

accept for mold design?

A: Common formats include STEP (.step/.stp), IGES (.iges/.igs), STL, DWG,

and native formats like SLDPRT or NX.

Final Thoughts

Selecting the right injection mold manufacturer can make or break

your product development timeline and production quality. A capable partner

will bring technical expertise, quality tooling, and dependable support to

ensure your product performs as intended.

Whether you're developing a single prototype or

launching a high-volume consumer product, taking the time to evaluate mold

manufacturers carefully is a smart investment in your product's success.