Injection mould design

Injection Mould Design: Key

Principles, Specifications & Best Practices

Injection mould design is one of the most critical stages in the plastic

part manufacturing process. A well-designed mould ensures product quality,

dimensional accuracy, repeatability, and cost efficiency. Whether

you’re developing a simple consumer item or a complex automotive component, a

robust mould design is essential to achieving consistent, defect-free

production.

In this blog, we’ll explore the fundamentals of injection mould design,

important specifications, design considerations, and answer frequently asked

questions to help guide your next tooling project.

What is Injection Mould Design?

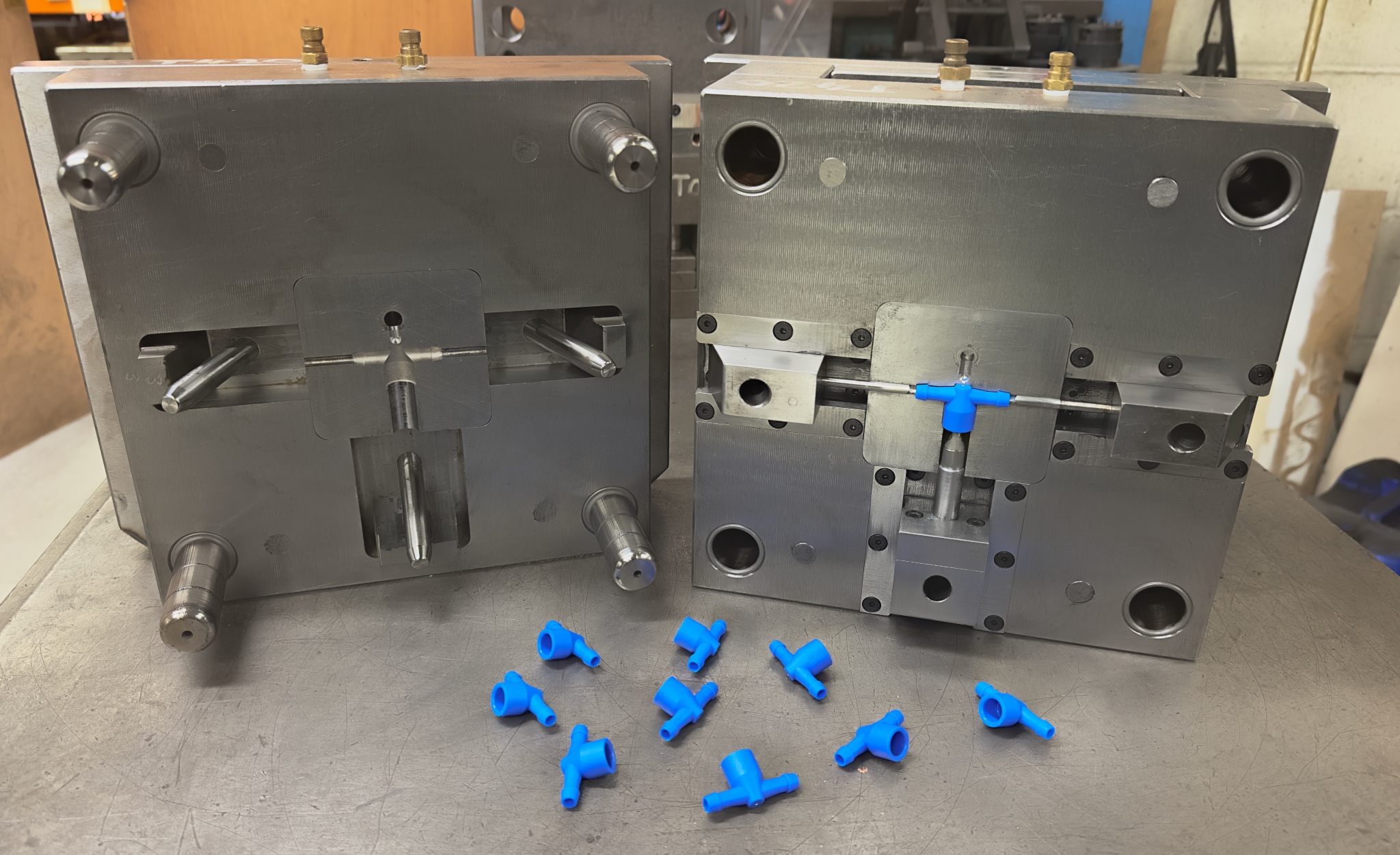

Injection mould design refers to the engineering and structuring of

moulds used in plastic injection moulding. The mould is a custom-fabricated

tool that shapes molten plastic into a solid form when injected under pressure.

A typical injection mould includes core and cavity plates, cooling

channels, runners, gates, and ejector systems. The design of these elements

directly impacts cycle time, part quality, cooling efficiency, and mould

life.

Types of Injection Moulds

Understanding the different types of moulds is crucial when initiating a

tooling project:

1. Two-Plate Mould

The most common type, ideal for simpler parts. The mould splits into two

halves — one fixed and one moving.

2. Three-Plate Mould

Features an extra plate to allow easier ejection and more flexible gate

placement, typically used for more complex or multi-gated parts.

3. Hot Runner Mould

Uses heated channels to maintain molten plastic within the runner system,

reducing waste and improving cycle time.

4. Cold Runner Mould

Allows the plastic in the runner to cool and solidify with each cycle.

It's cost-effective but creates more waste.

Specifications of a High-Performance

Injection Mould

Here are key technical specifications and design elements that define a

reliable injection mould:

|

Specification |

Typical Range / Description |

|

Mould Base Material |

Tool Steel (P20, H13), Aluminum |

|

Core & Cavity Material |

Hardened Steel, Stainless Steel |

|

Mould Life |

100,000 to 1,000,000+ cycles |

|

Cooling System Efficiency |

Optimized with baffles, channels, or conformal cooling |

|

Tolerance Capability |

±0.01 mm to ±0.05 mm |

|

Ejection System |

Ejector pins, sleeves, lifters, stripper plates |

|

Gate Types |

Edge gate, Pin gate, Valve gate, Submarine gate |

|

Surface Finishes |

VDI, SPI, EDM textured, high-polish |

Key Considerations in Injection Mould

Design

Designing a mould involves a balance between function, durability, and

manufacturability. Below are the essential design factors:

1. Part Geometry

Understanding the shape and complexity of the part is critical. Sharp

corners and uneven wall thicknesses should be avoided to reduce stress concentrations

and improve flow.

2. Wall Thickness

Uniform wall thickness ensures consistent cooling and reduces defects

like warping or sink marks. Aim for walls between 1 mm to 4 mm,

depending on the part size and material.

3. Draft Angles

Include draft (typically 1° to 3°) to facilitate easy part

ejection from the mould without damaging the part.

4. Cooling Channel Design

Efficient cooling is essential for reducing cycle time and improving part

consistency. Use optimized baffle and channel placements to evenly cool the

mould.

5. Material Selection

Choose the right material for the mould components based on the expected

production volume, cycle time, and type of plastic being moulded.

6. Venting

Proper venting prevents trapped air and gas burns. Vents should be

strategically placed in low-pressure areas.

Common Challenges in Mould Design

Even experienced designers encounter issues. Here are some common

problems and how to avoid them:

- Short Shots: Caused by

inadequate venting or poor runner design.

- Flash: Results from

excessive injection pressure or worn parting lines.

- Warping: Uneven

cooling or inconsistent wall thickness.

- Sink Marks: Thick

sections that cool slower than surrounding areas.

Early collaboration between the product designer and toolmaker is key to

solving these issues before production begins.

FAQs About Injection Mould Design

Q1. How long does it take to design

and build an injection mould?

A: The design phase typically takes 1–3 weeks, while mould fabrication can

take 4–8 weeks depending on complexity and revisions.

Q2. What’s the difference between

prototype and production moulds?

A: Prototype moulds are usually made from aluminum and built quickly for

low-volume testing, while production moulds use hardened steel for durability

and mass production.

Q3. Can a single mould produce

multiple parts?

A: Yes, multi-cavity moulds are designed to produce multiple identical

parts per cycle, while family moulds can create different parts in the same

mould.

Q4. How do I choose between a hot

runner and cold runner mould?

A: Choose hot runners for high-volume, waste-reduction, and better flow

control. Cold runners are simpler and more cost-effective for lower-volume

applications.

Q5. What software is used for mould

design?

A: Common tools include SolidWorks, Siemens NX, AutoCAD, CATIA, and Moldflow

for simulation and analysis.

Final Thoughts

Injection mould design is the foundation of any successful plastic injection

moulding project. A well-designed mould can improve product quality, reduce

production costs, and extend tool life dramatically.

Investing time in mould design, simulation, and collaboration with skilled toolmakers pays off in the long run. Whether you're building a single prototype or launching mass production, understanding the principles of mould design helps you make smarter decisions for your product and business.