Injection Moulding Company

Injection Moulding Company: Your

Partner in High-Volume Plastic Manufacturing

In today’s fast-paced manufacturing landscape, choosing the right injection

moulding company can make all the difference in bringing your product to

market efficiently and cost-effectively. These companies play a critical role

in producing complex, high-precision plastic components at scale for industries

such as automotive, medical, electronics, packaging, and consumer goods.

In this comprehensive guide, we’ll explore what an injection moulding

company does, their core capabilities, technical specifications, how to choose

the right partner, and answer frequently asked questions.

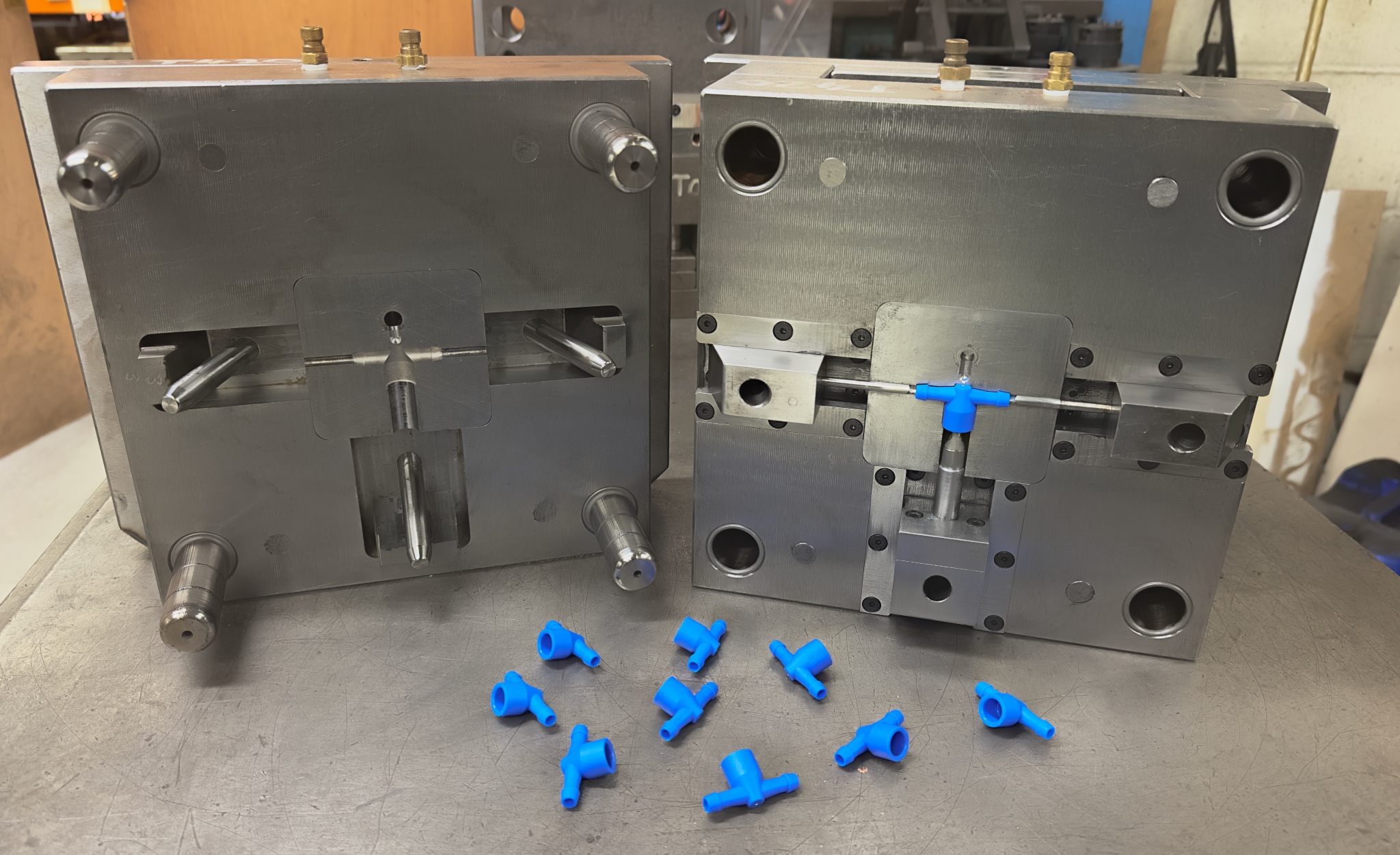

What Is an Injection Moulding Company?

An injection moulding company specializes in the production of

plastic parts using a manufacturing process where molten plastic is injected

into a mould. Once cooled, the plastic hardens into the final shape. These

companies typically offer a range of services including part design, mould

fabrication, injection moulding, quality control, and post-processing.

Whether you need a few thousand components or millions annually, an

experienced injection moulding company ensures reliable, repeatable production

with minimal waste and high precision.

Core Services Offered by an Injection

Moulding Company

1. Product Design Support

From concept to CAD, injection moulding companies assist in designing

parts that are functional, manufacturable, and cost-effective. They also advise

on plastic material selection based on performance and application needs.

2. Mould Tooling Design &

Fabrication

Companies either build moulds in-house or work with dedicated tool rooms

to develop steel or aluminum moulds with precise cavity design and cooling

channels.

3. Plastic Injection Moulding

Production

High-speed, automated injection moulding machines produce plastic parts

with consistent quality and tight tolerances.

4. Quality Assurance and Testing

Through dimensional inspections, material certification, and in-process

monitoring, companies maintain quality throughout production.

5. Post-Processing Services

These can include trimming, ultrasonic welding, pad printing, assembly,

packaging, and more—delivering ready-to-market products.

Technical Specifications to Consider

Below is a table of standard specifications and capabilities offered by

leading injection moulding companies:

|

Specification |

Typical Range or Options |

|

Clamping Force |

30 – 5,000 tons |

|

Machine Shot Size |

1g – 10+ kg |

|

Cycle Time |

10 – 60 seconds |

|

Mould Cavities |

Single, Multi-cavity (2, 4, 8, 16, 32+) |

|

Supported Thermoplastics |

ABS, PC, PA, PP, PE, TPE, POM, PEEK |

|

Mould Materials |

Hardened Steel (P20, H13, S136), Aluminum |

|

Tolerance Accuracy |

±0.01 mm – ±0.05 mm |

|

Surface Finish Options |

SPI (A1-D3), VDI textures, EDM, matte or gloss polish |

|

Quality Certifications |

ISO 9001, IATF 16949, ISO 13485, AS9100 |

|

Production Volume |

Low-volume (1,000 units) to high-volume (millions/year) |

Industries Served by Injection

Moulding Companies

Injection moulding is a versatile process, enabling companies to serve a

broad range of sectors:

- Automotive: Dashboards,

grilles, door handles, under-hood parts

- Medical: Syringes,

inhalers, surgical instruments, diagnostics housings

- Consumer

Electronics: Remote controls, keyboard housings, plugs

- Industrial

Equipment: Enclosures, panels, fasteners

- Packaging: Bottle caps,

food containers, tamper-evident lids

- Toys &

Sports: Action figures, helmet parts, water bottles

Each industry has unique standards, and working with a company familiar

with your sector’s requirements is crucial.

How to Choose the Right Injection

Moulding Company

Choosing a moulding partner should be a strategic decision. Here’s what

to look for:

1. Technical Capability

Ensure the company has modern machinery, experienced engineers, and

in-house toolmaking or strong partnerships.

2. Material Expertise

Different applications require different plastics. The company should

offer guidance on polymers based on mechanical, thermal, or chemical resistance

needs.

3. Volume Flexibility

Some companies focus on prototyping or low-volume runs, while others are

built for high-volume production. Choose one that aligns with your needs.

4. Certifications and Compliance

ISO or industry-specific certifications show a commitment to quality

control and traceability—critical for automotive, medical, and aerospace parts.

5. Location and Logistics

Consider lead time, shipping cost, and support availability. Local

manufacturers may offer faster turnarounds and easier communication.

FAQs About Injection Moulding

Companies

Q1: What’s the typical lead time for

injection moulding production?

A: Once the mould is ready, production lead time is typically 1–4 weeks,

depending on part complexity and volume.

Q2: Can injection moulding be used for

low-volume production?

A: Yes. Some companies offer rapid tooling or aluminum moulds

specifically for small-batch or prototype production.

Q3: How much does it cost to have a

part injection moulded?

A: Costs vary depending on tooling complexity, part size, material, and

volume. Tooling can range from $3,000 to $100,000+, while per-part costs drop

significantly at higher volumes.

Q4: What’s the difference between hot

runner and cold runner systems?

A: Hot runners keep the plastic molten inside the runner system, reducing

waste and cycle time. Cold runners allow the runner to solidify, which is more

cost-effective but generates more waste.

Q5: Do injection moulding companies

offer design consultation?

A: Yes, most companies offer Design for Manufacturability (DFM)

analysis to ensure your part design suits the moulding process and minimizes

defects.

Final Thoughts

Working with the right injection moulding company can transform

your idea into a scalable, market-ready plastic product. From part design to

mass production, a trusted partner ensures every stage of the process meets

your performance, cost, and time requirements.

As you evaluate potential suppliers, look for technical expertise, quality assurance, material knowledge, and transparent communication. Investing in a reliable moulding partner means more than just manufacturing—it means building long-term value for your brand.