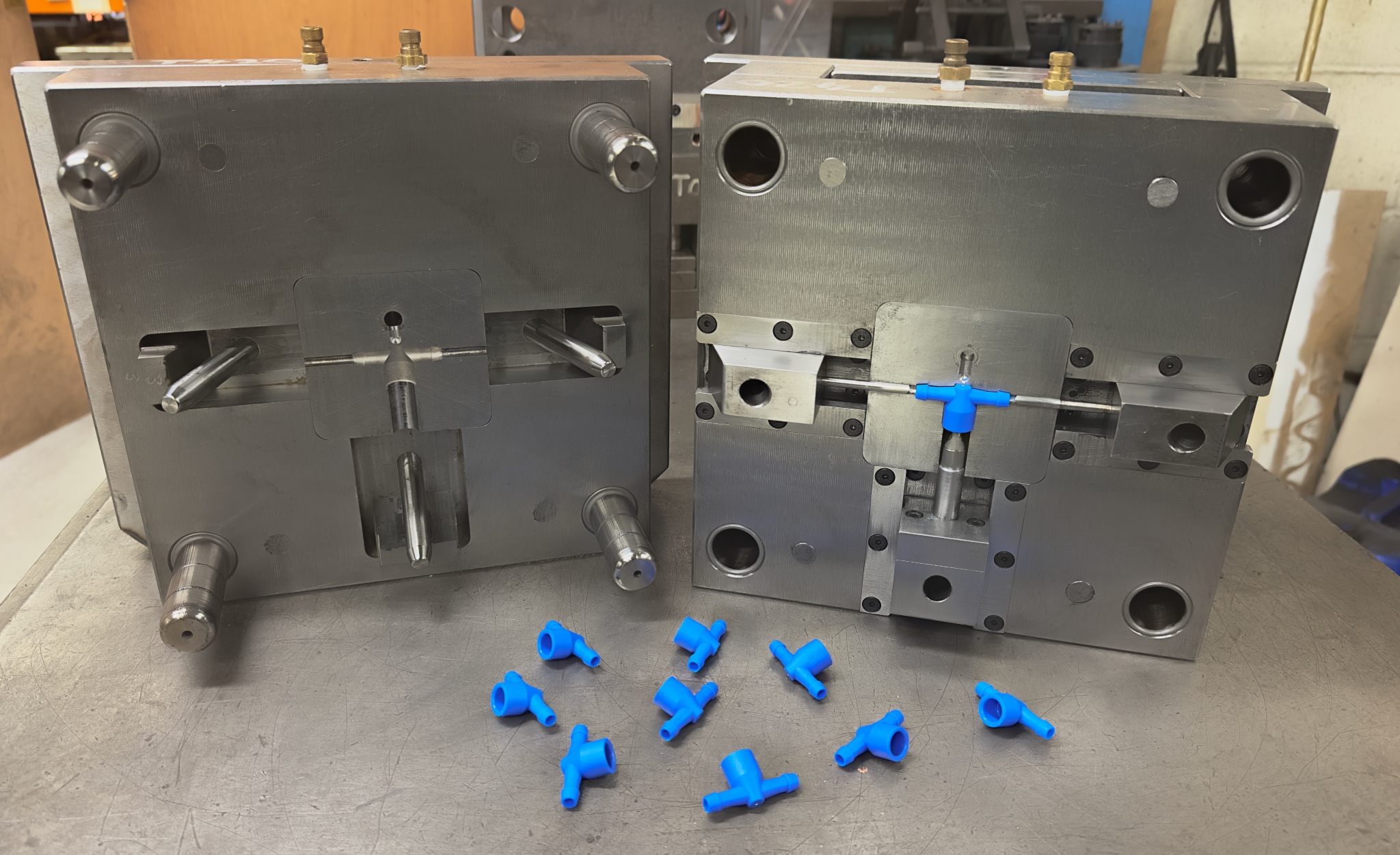

Injection moulding mold

Injection Moulding Mold: The Engine Behind High-Precision Plastic

Manufacturing

In today’s fast-paced manufacturing industry, injection moulding molds

are essential tools that enable the mass production of high-quality plastic

components. These molds serve as the backbone of the injection moulding

process, providing precision, efficiency, and repeatability across a range of

industries—from automotive and electronics to medical and consumer goods.

This blog explores what injection moulding molds are, their components,

key technical specifications, and what to consider when designing or sourcing

one. We’ll also answer frequently asked questions to help you gain a complete

understanding of this vital manufacturing element.

What Is an Injection Moulding Mold?

An injection moulding mold is a custom-engineered tool used in the

plastic injection moulding process. It shapes molten plastic into a final

product by forcing the material into a mold cavity, allowing it to cool and

solidify.

These molds are typically made from hardened steel or aluminum and are

designed to produce thousands to millions of identical parts with high

precision. The design and build of the mold significantly influence the final

product’s quality, production speed, and manufacturing cost.

Key Components of an Injection

Moulding Mold

An injection mould consists of several interconnected parts, each

performing a specific function during the molding cycle.

1. Core and Cavity

The cavity forms the external shape of the plastic part, while the

core shapes internal features. Together, they define the product’s

geometry.

2. Sprue, Runners, and Gates

These channels guide molten plastic from the injection nozzle to the mold

cavity. The sprue is the main entry, runners distribute the

material, and gates control its flow into each cavity.

3. Cooling System

Molds contain water channels or cooling circuits to manage the

temperature during production. Proper cooling ensures dimensional stability and

reduces cycle time.

4. Ejection System

Once the plastic has solidified, ejector pins, plates, or air

ejectors push the part out of the mold.

5. Ventilation

Air vents allow trapped gases to escape, preventing burn marks or short

shots on the molded parts.

Technical Specifications of an

Injection Moulding Mold

Choosing or designing a mold requires careful attention to its

specifications. Below is a table outlining typical features and their ranges:

|

Specification |

Details |

|

Mold Material |

Hardened Steel (P20, H13, S136), Aluminum (Prototypes) |

|

Mold Life |

100,000 to 1,000,000+ cycles |

|

Number of Cavities |

1, 2, 4, 8, 16, 32+ |

|

Dimensional Tolerances |

±0.01 mm to ±0.05 mm |

|

Surface Finishes |

SPI Grades (A1–D3), VDI, EDM, Mirror Polish |

|

Cooling System |

Conventional or Conformal Cooling |

|

Runner Systems |

Cold Runner, Hot Runner |

|

Gate Types |

Submarine, Edge, Pin, Valve Gate |

|

Ejection Mechanism |

Ejector Pins, Sleeves, Plates, Air Ejectors |

|

Software for Design |

SolidWorks, AutoCAD, NX, Moldflow, CATIA |

Types of Injection Moulding Molds

1. Prototype Molds

These are typically made from aluminum and used for short runs or product

testing. They are cost-effective and ideal for quick iterations.

2. Production Molds

Made from hardened steel, production molds are built for durability and

high-volume manufacturing.

3. Multi-Cavity Molds

These molds produce multiple parts per cycle, boosting efficiency and

reducing per-part costs.

4. Family Molds

Used to produce different parts from the same material in one mold—common

for assemblies like caps and containers.

Advantages of High-Quality Injection

Moulding Molds

- ✅ Precision and Repeatability: Consistent output across high

volumes.

- ✅ Faster Cycle Times: Optimized cooling and ejection systems

reduce downtime.

- ✅ Durability: Long-lasting molds reduce the need for frequent

replacements.

- ✅ Reduced Defects: Advanced gating, venting, and cooling help

prevent cosmetic and structural flaws.

Considerations When Choosing or

Designing a Mold

1. Part Complexity

Intricate parts may require special gating, multiple cavities, or

advanced cooling systems.

2. Material Selection

Different plastics behave differently under heat and pressure—your mold

must be designed to accommodate specific flow, shrinkage, and cooling

characteristics.

3. Production Volume

For short runs, consider aluminum molds; for long-term production,

hardened steel is more cost-effective over time.

4. Budget

Balance initial mold cost with lifecycle savings. A higher upfront

investment often pays off in reduced maintenance and higher output quality.

FAQs About Injection Moulding Molds

Q1: How long does it take to build an

injection moulding mold?

A: Typically, it takes 4–12 weeks depending on the complexity, size,

and number of cavities.

Q2: What is the typical lifespan of a

mold?

A: Aluminum prototype molds may last up to 100,000 cycles, while

steel production molds can exceed 1,000,000 cycles with proper

maintenance.

Q3: Can a mold produce more than one

part at a time?

A: Yes. Multi-cavity molds and family molds allow the

production of multiple parts in a single cycle, improving efficiency.

Q4: What affects the cost of an

injection moulding mold?

A: Key factors include mold material, number of cavities, complexity of the

part, and cooling or runner systems.

Q5: How do hot runner and cold runner

systems differ?

A: Hot runners keep the plastic molten within the runner system, reducing

waste. Cold runners allow the material to solidify, requiring trimming and

creating more scrap.

Conclusion

An injection moulding mold is not just a tool—it’s the foundation

of efficient, high-volume plastic part production. From mold design and

material selection to tooling and cooling, every detail contributes to product

success.

Whether you're launching a new product or scaling up production,

investing in a well-designed mold pays off in consistent quality, lower part

costs, and reliable lead times. Partnering with experienced mold designers and

manufacturers can help you achieve faster time-to-market and long-term

manufacturing efficiency.