Injection moulding process

Injection Moulding Process: A Complete Guide for

Manufacturers

Injection moulding is one of the most important and widely used

manufacturing processes for producing high-precision plastic parts at scale.

Whether you're in the automotive, medical, electronics, or consumer goods

industry, the injection moulding process offers unmatched efficiency,

repeatability, and design flexibility.

This comprehensive guide will walk you through what injection moulding

is, how it works, its technical specifications, advantages, and key

considerations. We’ll also answer the most frequently asked questions to help

you better understand its applications.

What is Injection Moulding?

Injection moulding is a manufacturing process used to produce

parts by injecting molten material into a mould. Most commonly used with thermoplastic

and thermosetting polymers, the process is ideal for creating high-volume

parts with tight tolerances and complex geometries.

The process is highly automated, making it a cost-effective choice for

mass production.

How the Injection Moulding Process

Works

Injection moulding involves a series of systematic steps to ensure

precise shaping of plastic materials into finished products.

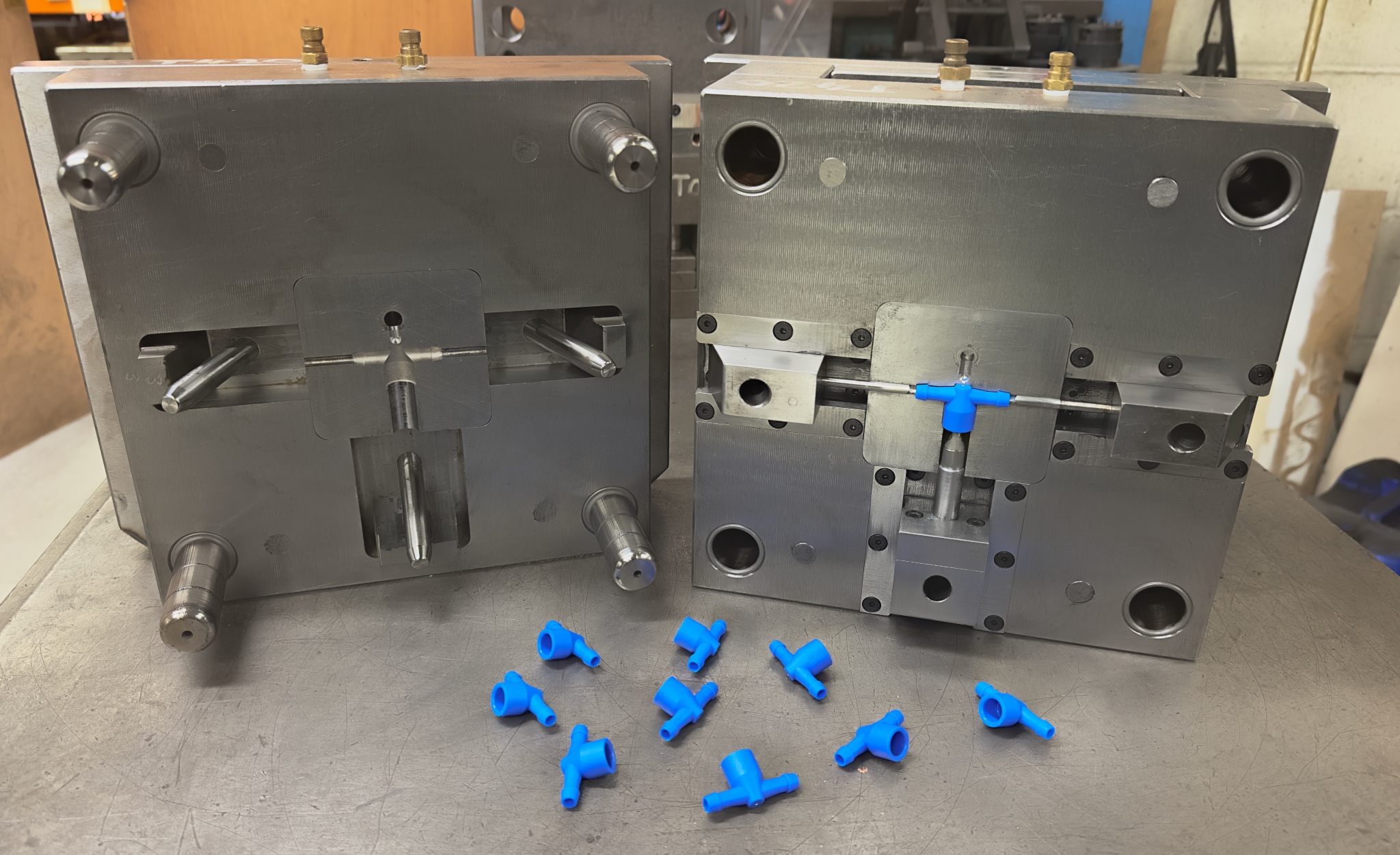

1. Mould Clamping

The process begins with clamping the mould halves together using a

powerful hydraulic or mechanical press. This forms a closed cavity for the

molten plastic.

2. Material Injection

Plastic pellets are fed into a heated barrel, melted, and injected into

the mould at high pressure through a screw system.

3. Cooling Phase

Once inside the mould, the plastic cools and solidifies into the final

shape. The cooling time depends on part thickness and material type.

4. Ejection

After the plastic has solidified, the mould opens, and ejector pins push

the finished part out of the cavity.

Injection Moulding Specifications

Below are the common specifications and parameters that define the

performance and capabilities of an injection moulding system:

|

Parameter |

Specification |

|

Materials |

Thermoplastics, Thermosets, Elastomers |

|

Injection Pressure |

70 to 140 MPa |

|

Clamping Force |

20 to 5,000 tons |

|

Shot Size |

1 gram to several kilograms |

|

Mould Cavity Pressure |

35 to 140 MPa |

|

Cycle Time |

10 to 60 seconds |

|

Tolerances |

±0.1 mm or tighter |

|

Surface Finishes |

Smooth, Textured, Matte, Glossy |

|

Tooling Materials |

Steel, Aluminum |

Advantages of Injection Moulding

Injection moulding offers a variety of benefits that make it the go-to

process for manufacturing plastic parts:

1. High Production Efficiency

The cycle times are short, and once the tooling is developed, parts can

be produced rapidly in high volumes.

2. Precision and Consistency

Ideal for producing parts with complex geometries and tight tolerances

across millions of cycles.

3. Material Variety

Compatible with a wide range of materials to achieve desired physical,

chemical, and aesthetic properties.

4. Minimal Waste

The process generates little material waste, and excess material can

often be reground and reused.

5. Low Labor Costs

Highly automated machines reduce manual labor and increase cost

efficiency.

Applications of Injection Moulding

Injection moulding is used across a wide spectrum of industries due to

its flexibility and reliability:

- Automotive: Dashboards,

bumpers, gear knobs

- Consumer

Products: Plastic containers, toys, appliance components

- Medical: Syringes,

diagnostic devices, prosthetics

- Packaging: Bottle caps,

closures, custom packaging

- Electronics: Phone

housings, connectors, circuit board casings

Key Design Considerations

Before starting the injection moulding process, consider the following

design principles for optimal performance:

1. Wall Thickness

Maintain uniform wall thickness to prevent defects like warping or sink

marks.

2. Draft Angles

Add tapering to vertical walls to facilitate smooth ejection from the

mould.

3. Undercuts and Ribs

Minimize undercuts to reduce tooling complexity and incorporate ribs for

structural strength.

4. Material Selection

Choose materials based on impact strength, flexibility, heat resistance,

or regulatory requirements.

FAQs About the Injection Moulding

Process

Q1. What materials are best suited for

injection moulding?

A: Common materials include ABS, Polypropylene, Nylon, Polyethylene, and

Polystyrene. The best material depends on your part’s function and environment.

Q2. What is the cost of creating an

injection mould?

A: Tooling costs can range from $5,000 to over $100,000 depending on size,

complexity, and material of the mould. However, the cost per part decreases

with volume.

Q3. Can injection moulding be used for

low-volume production?

A: While it’s traditionally used for high volumes, low-volume runs are

possible with aluminum moulds or rapid tooling methods.

Q4. How long does a mould last?

A: A steel mould can last for over a million cycles with proper

maintenance, while aluminum tools have shorter lifespans.

Q5. Is injection moulding

environmentally friendly?

A: It can be sustainable when using recyclable plastics and optimizing

material usage. Energy-efficient machines and regrind systems also reduce the

environmental footprint.

Final Thoughts

Injection moulding is a time-tested manufacturing technique that provides

speed, precision, and scalability. With careful attention to design, tooling,

and material selection, it can help companies across industries bring

high-quality products to market efficiently.

Whether

you’re prototyping a new product or scaling up for mass production,

understanding the injection moulding process is essential for achieving both

quality and cost-effectiveness.