Mould development process

Understanding the Mould Development

Process: A Comprehensive Guide

Mould development plays a pivotal role in various industries,

particularly in manufacturing, where precision and efficiency are paramount.

Whether you're creating plastic components, automotive parts, or any other

product requiring moulds, understanding the development process is essential

for ensuring high-quality results. This guide will walk you through the stages

of mould development, key specifications to consider, and common challenges

manufacturers face.

What is Mould Development?

Mould development is the process of designing and creating a mould, a

tool used to shape materials into a specific form. These moulds can be made

from a variety of materials, including steel, aluminum, or other metals, and

are used in injection molding, compression molding, and other manufacturing

techniques. Moulds are crucial in ensuring that products are made with the

correct dimensions, strength, and durability.

Stages of the Mould Development

Process

The process of mould development is intricate and involves several

phases, from initial design to the final production run. Let's break down each

step:

1. Conceptualization and Design

The first stage in mould development involves designing the mould based

on the product’s specifications. This step requires collaboration between

engineers, designers, and manufacturers. Computer-aided design (CAD) software

is typically used to create a digital representation of the product and the

mould. This design will dictate the shape, size, and features of the final

mould. Specifications to consider include:

- Material choice: The type of

material selected for the mould will impact its durability and

performance. Common materials include hardened steel, aluminum, and

various alloys.

- Shape and size

of the product: The mould design needs to accommodate the product’s dimensions,

complexity, and any specific design features like holes, threads, or

undercuts.

- Cooling

channels: To prevent defects like warping, efficient cooling channels need

to be incorporated into the mould design to maintain a consistent

temperature during the molding process.

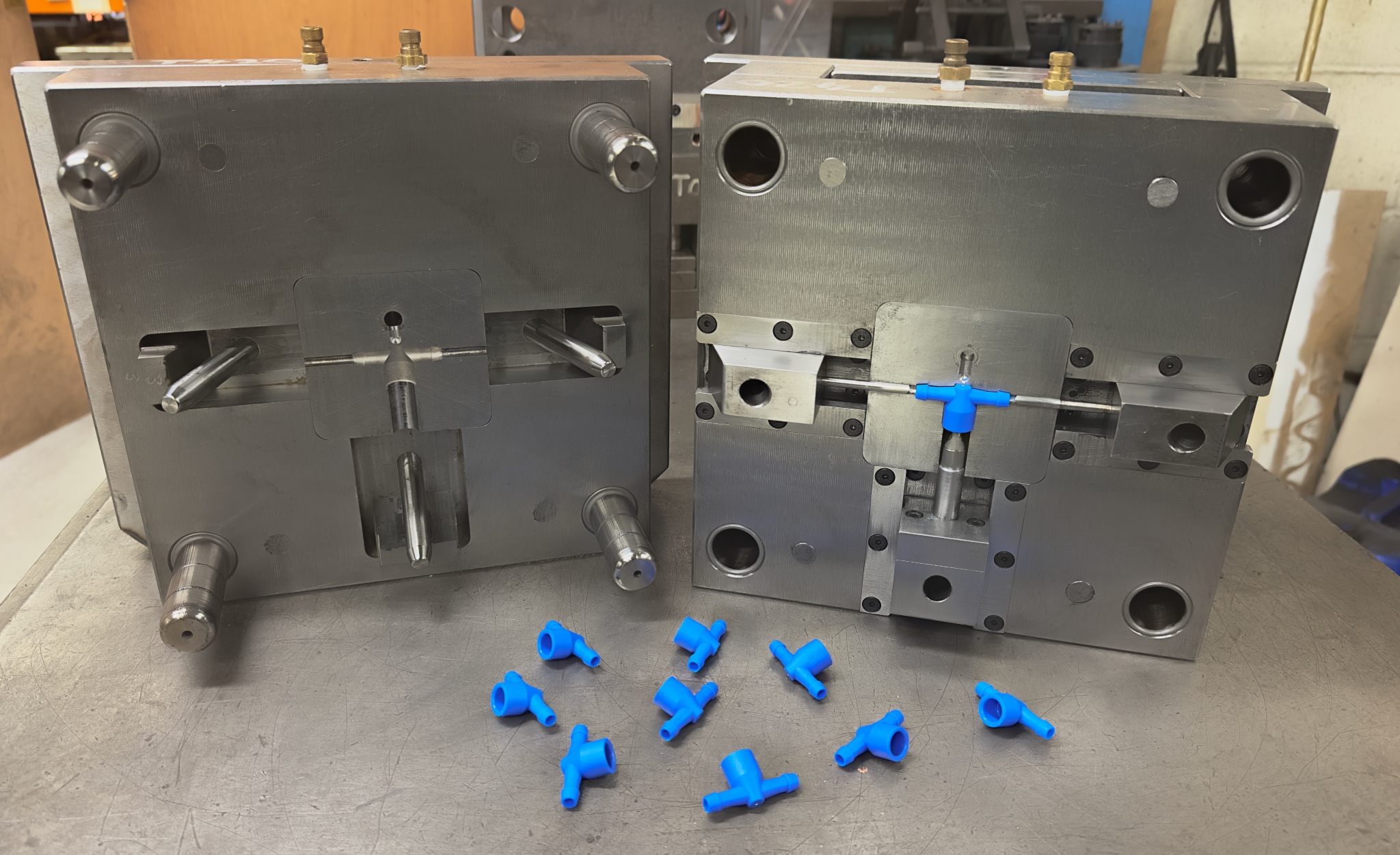

2. Mould Fabrication

Once the design is finalized, the next step is to fabricate the mould.

This phase involves precision machining, which can include:

- CNC machining: Computer

Numerical Control (CNC) machines are used to cut, shape, and carve the

mould based on the CAD design. CNC machines provide high precision,

ensuring that the final mould is accurate.

- Injection and

molding tools: These tools are carefully crafted to create cavities, channels,

and other essential features required for molding the desired product. The

design must ensure that the part can be easily ejected from the mould once

it’s formed.

3. Mould Testing and Trial Runs

After fabrication, the mould undergoes testing and trial runs. During

this phase, manufacturers inject the raw material into the mould to ensure that

it can create the product without issues. The goal of the trial run is to

detect any design flaws or issues, such as:

- Incomplete

filling of the cavity.

- Surface defects

such as air bubbles or excessive flash.

- Difficulty

ejecting the product.

If the product does not meet specifications, adjustments are made to the

mould design, cooling system, or injection process. Multiple trial runs may be

necessary to perfect the mould.

4. Final Production and Optimization

Once the trial run is successful and the mould is deemed optimal,

full-scale production begins. In this stage, the mould is used to manufacture

large quantities of the product. During this phase, the process is constantly

monitored and optimized to ensure maximum efficiency and product quality. Key

factors include:

- Cycle time: The time it

takes to produce each part. Shorter cycle times lead to higher production

rates.

- Material waste: Efforts are

made to minimize waste and optimize the use of raw materials during the

manufacturing process.

- Maintenance: Regular maintenance

of the mould is crucial to ensure its longevity and consistent performance

throughout production.

5. Post-Production and Quality Control

After the production run, products undergo quality control to ensure they

meet the required standards. The mould is also inspected for wear and tear, and

any necessary repairs or modifications are made. If the mould is used for a

high-volume production run, it may need periodic refurbishment to maintain

optimal performance.

Key Specifications to Consider in

Mould Development

When developing a mould, several key specifications must be taken into

account to ensure its success in production:

- Material

selection: The type of material used for both the mould and the product plays

a significant role in the mould's longevity and the product’s strength.

For example, hardened steel is often used for molds that require long

lifespans and high precision.

- Mould cavity: The cavity is

where the molten material is injected. The design of the cavity must

account for uniform flow, cooling, and easy removal of the part.

- Mould lifespan: The lifespan

of the mould depends on factors such as material hardness, cooling system

efficiency, and maintenance practices.

- Tolerances and

finishes: The mould must be designed with very tight tolerances to ensure

the product meets the necessary specifications. Surface finishes are also

important for aesthetics and functionality.

Frequently Asked Questions (FAQs)

1. What materials are commonly used in

mould development?

Moulds can be made from various materials, including hardened steel,

aluminum, and beryllium copper alloys. Each material has its own advantages

depending on the application, such as hardness, resistance to wear, and heat

dissipation.

2. How long does the mould development

process take?

The time required for mould development can vary depending on the

complexity of the product and the mould itself. On average, the process can

take anywhere from a few weeks to several months, particularly when multiple

iterations of testing and adjustments are required.

3. What is the cost of developing a

mould?

The cost of mould development depends on factors such as the size and

complexity of the mould, material used, and the number of trial runs required.

Simple moulds can cost a few thousand dollars, while more intricate and

large-scale moulds can exceed tens of thousands.

4. How do I know if my mould needs

maintenance?

Moulds require regular inspections for signs of wear and tear, such as

cracks, rust, or degradation of the cooling system. If defects begin to appear

in the molded parts, it may be time for maintenance or refurbishment.

5. What are some common challenges in

mould development?

Challenges in mould development include issues with design accuracy,

material selection, cooling inefficiencies, and difficulties in product

ejection. Each of these challenges can impact production efficiency and product

quality.

Conclusion

The mould development process is a critical aspect of modern manufacturing. From the initial design to the final product, each step of the process plays a crucial role in determining the quality and efficiency of the manufacturing process. By understanding the stages involved and the specifications required, manufacturers can ensure that their moulds deliver precise, high-quality products while minimizing costs and production time