Plastic Injection Company

Plastic Injection Company: Leading

the Way in High-Quality Manufacturing Solutions

In today’s fast-paced and ever-evolving manufacturing landscape, plastic

injection molding plays a crucial role in producing high-quality, precise,

and durable plastic components. Whether for the automotive, electronics,

medical, or consumer goods industries, plastic injection molding companies are

at the forefront of creating parts that meet stringent industry standards.

In this blog post, we’ll explore the role of a plastic injection

company, how they operate, the services they provide, key specifications to

consider, and answer frequently asked questions to give you a complete

understanding of the industry.

What Is a Plastic Injection Company?

A plastic injection company specializes in the design, production,

and manufacturing of plastic components through the injection molding process.

This process involves injecting molten plastic into a precisely crafted mold,

where it cools and solidifies into the desired shape. These companies cater to

a variety of industries by producing parts such as automotive components,

medical devices, packaging materials, and consumer products.

The success of a plastic injection company is based on the combination of

advanced machinery, experienced engineers, and a deep understanding of material

properties. They work with clients to turn concepts into reality, providing

prototypes, production molds, and ongoing support.

How Plastic Injection Companies

Operate

Plastic injection companies offer a range of services that cover

everything from initial design to mass production. Here’s an overview of how

they typically operate:

1. Initial Consultation and Design

The process starts with a detailed consultation to understand the

client’s needs. During this stage, the company evaluates factors like part

geometry, material selection, and production volume. A team of designers and

engineers works with the client to create a mold design using CAD

(Computer-Aided Design) software.

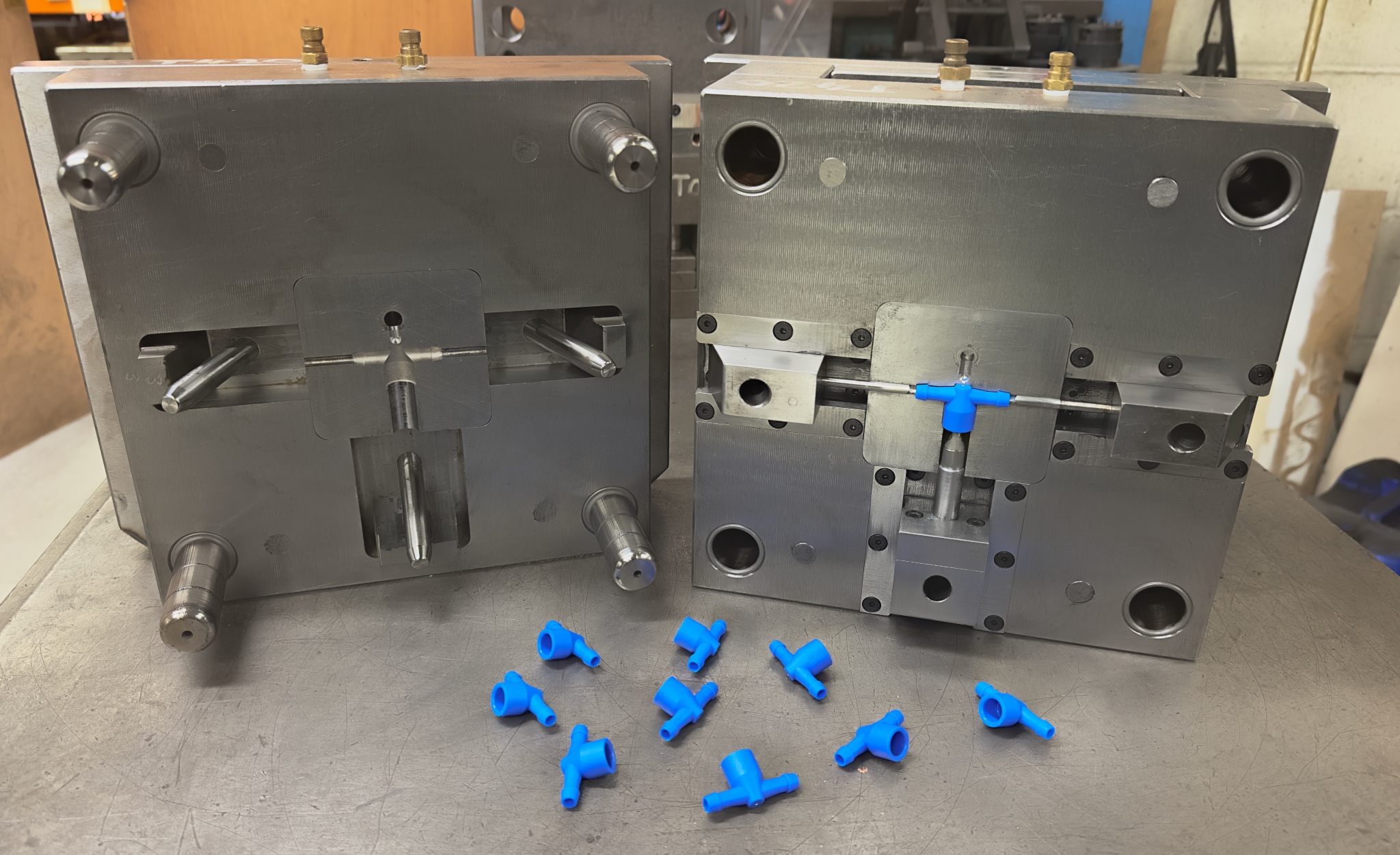

2. Tooling and Prototyping

Once the design is finalized, the company fabricates the necessary

tooling—molds that will be used for injection molding. Prototyping is often

done to ensure that the design functions as intended and that there are no

issues with fit, function, or material flow.

3. Production

After prototyping, the company begins the mass production phase. The

plastic material (usually in the form of pellets) is melted and injected into

the mold, where it takes shape and solidifies. The entire process is optimized

for speed, precision, and repeatability to produce large quantities of

identical parts.

4. Quality Control

Quality is a top priority in plastic injection companies. Every part is

subject to rigorous quality control checks, which may include dimensional

inspections, material testing, and stress testing to ensure the parts meet

industry standards.

5. Packaging and Shipping

Once the parts pass inspection, they are packaged and shipped to the

client. Some companies also offer post-production services, such as assembly,

decorating, and finishing, to ensure the final product is ready for use.

Specifications of Plastic Injection

Services

When choosing a plastic injection company, it’s important to

consider the technical specifications of the services they provide. Here’s a

breakdown of some key specifications:

|

Specification |

Details |

|

Materials Used |

ABS, Polycarbonate, Nylon, PVC, Polyethylene, etc. |

|

Mold Material |

Steel (P20, H13, S136), Aluminum (for prototypes) |

|

Tolerance |

±0.01 mm to ±0.05 mm for high precision |

|

Injection Pressure |

10,000 to 30,000 PSI (depending on material and part size) |

|

Cycle Time |

Typically 15-60 seconds per cycle |

|

Cavities |

Single cavity, multi-cavity, family molds |

|

Part Size |

Small (1 inch) to large (50+ inches) |

|

Surface Finish |

SPI grades, mirror finish, textured, matte, gloss |

A reliable plastic injection company can provide these specifications to

meet the exact requirements of your product, ensuring high-quality production

at scale.

Industries That Benefit from Plastic

Injection Molding

Plastic injection molding is a versatile process that serves numerous

industries. Some of the industries that rely heavily on plastic injection

companies include:

1. Automotive Industry

Plastic components are essential in the automotive industry for producing

interior and exterior parts such as dashboard components, bumpers, and housings

for electrical systems.

2. Medical Devices

Injection-molded plastic parts are crucial in the medical field for

creating components such as syringes, IV connectors, and diagnostic tools. These

parts must meet strict regulatory standards for safety and quality.

3. Consumer Goods

Many household products, including kitchen tools, electronics, toys, and

packaging, are made using injection molding. Plastic injection companies help

design and manufacture products with durability, precision, and aesthetic

appeal.

4. Electronics

Plastic injection molding is widely used in the production of electronic

devices. Components like casings, connectors, and housing for mobile phones,

computers, and appliances are often produced using this method.

FAQs About Plastic Injection

Companies

Q1: What are the advantages of using a

plastic injection company for manufacturing?

A: Some key advantages include cost-effectiveness for large-scale

production, high precision, the ability to work with a wide range of materials,

and fast cycle times. It’s ideal for producing large quantities of identical

parts with minimal waste.

Q2: How long does it take to create a

mold for production?

A: The time to create a mold typically ranges from 4 to 12 weeks,

depending on the complexity of the design, the number of cavities, and the

material used. Prototypes may take less time to produce.

Q3: What materials are used in plastic

injection molding?

A: Common materials include ABS, polycarbonate, nylon, polypropylene,

PVC, polyethylene, and polystyrene. The choice of material depends

on factors like strength, flexibility, temperature resistance, and application

needs.

Q4: Can a plastic injection company

produce both small and large parts?

A: Yes, plastic injection companies can produce parts of varying sizes,

from tiny components like connectors to large parts such as automotive bumpers.

The equipment and molds are tailored to the specific part size.

Q5: What happens if there’s a defect in

a molded part?

A: If a defect is detected, the part is typically discarded. Plastic

injection companies conduct rigorous quality control checks to identify defects

before the parts are shipped. If necessary, the molds can be modified to

correct the issue.

Conclusion

Plastic injection companies are essential players in modern manufacturing,

providing high-quality, efficient solutions for producing a wide range of

plastic components. Whether you're developing a new product or scaling up

production, choosing the right injection molding company is key to ensuring

precision, cost-effectiveness, and reliability.

With advanced technologies, skilled teams, and years of industry experience, plastic injection companies are equipped to handle diverse manufacturing needs across a wide range of industries.