Plastic Injection Molded Parts

Plastic Injection Molded Parts: The

Backbone of Modern Manufacturing

Plastic injection molding is one of the most common and versatile manufacturing

processes in the world today. It’s used to create a vast array of products,

from everyday household items to high-precision automotive and medical

components. The plastic injection molded parts that result from this

process are critical in many industries due to their precision, durability, and

cost-effectiveness.

In this blog post, we’ll explore the world of plastic injection molded

parts, dive into the process, specifications, and applications, and answer some

common questions to help you better understand how these parts are made and

their importance in various industries.

What Are Plastic Injection Molded

Parts?

Plastic injection molded parts are components created using the injection

molding process. This process involves injecting molten plastic into a mold

cavity at high pressure. Once cooled, the plastic solidifies, taking the shape

of the cavity, resulting in a finished part. This method is highly efficient

and ideal for producing large volumes of identical parts with high precision.

These molded parts are used in a wide variety of applications, from

consumer electronics to automotive parts, medical devices, and packaging

materials. The versatility and adaptability of plastic injection molding make

it the preferred choice for manufacturers across the globe.

The Plastic Injection Molding Process

1. Material Selection

The first step in producing plastic injection molded parts is choosing

the right material. Depending on the part’s intended use, manufacturers select

from a range of plastic materials such as ABS, Polycarbonate, Nylon,

Polypropylene, and PVC. Each material has unique properties that

make it suitable for different applications.

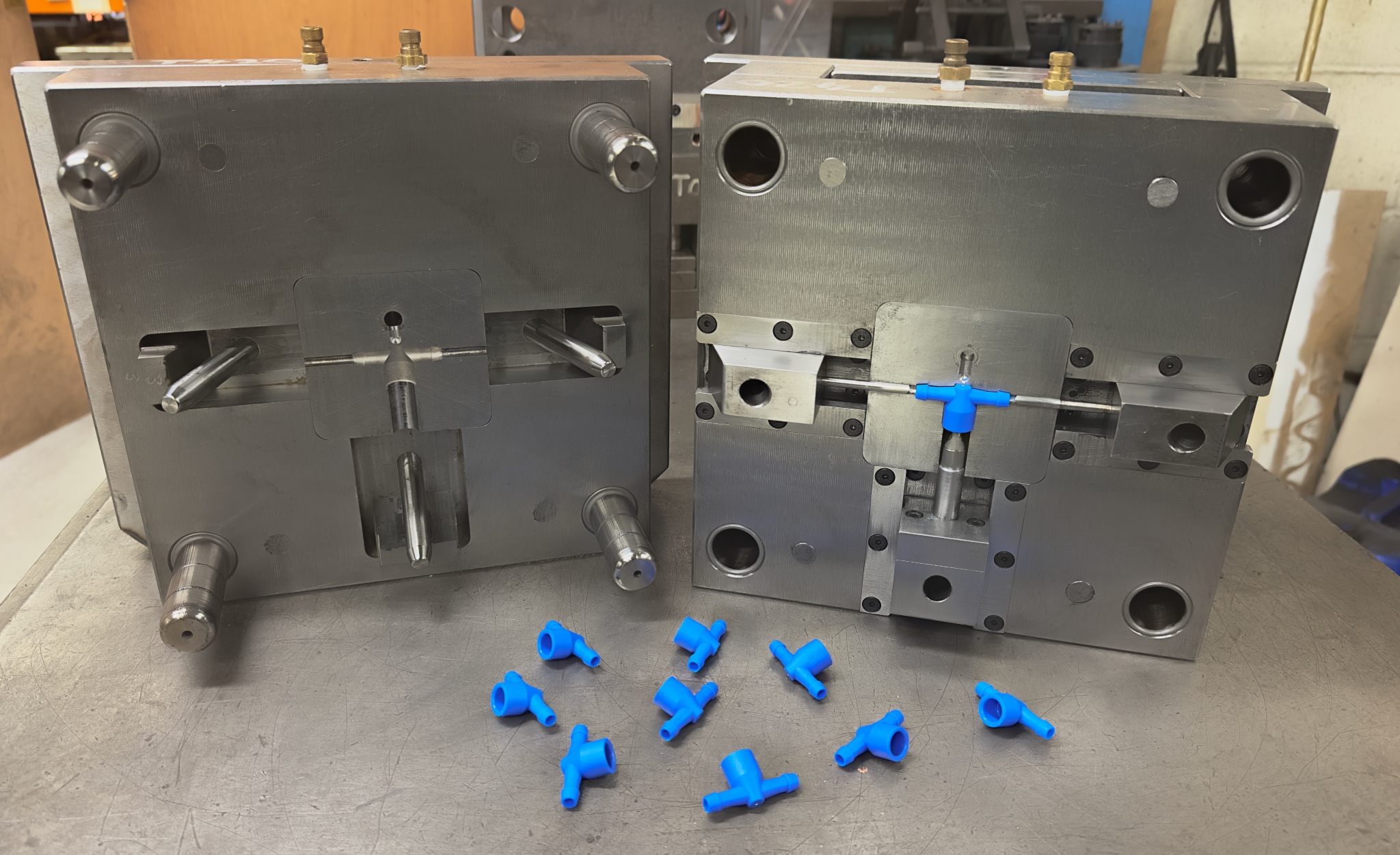

2. Mold Design and Fabrication

The next step involves designing the mold, which is a critical part of

the process. Computer-Aided Design (CAD) software is used to create a 3D

model of the part. Once the design is finalized, the mold is fabricated,

usually from high-quality steel or aluminum, depending on the

production requirements. The mold must be precisely manufactured to ensure that

the resulting parts are accurate and consistent.

3. Injection and Cooling

Once the mold is ready, the plastic material, typically in pellet form,

is heated until it becomes molten. The molten plastic is injected into the mold

under high pressure, where it fills the cavity. Afterward, the part is allowed

to cool and solidify within the mold. This cooling time varies depending on the

material used and the thickness of the part.

4. Ejection and Finishing

After the part has cooled and solidified, it is ejected from the mold. At

this stage, some parts may require additional finishing, such as trimming,

polishing, or painting to meet aesthetic or functional

requirements. The finished parts are then inspected for quality and consistency

before being packaged for shipment.

Specifications of Plastic Injection

Molded Parts

The success of plastic injection molded parts is determined by several

key specifications. Understanding these factors is essential for ensuring that

the final parts meet both functional and quality standards. Here are some

critical specifications to consider:

|

Specification |

Details |

|

Material Options |

ABS, Polycarbonate, Nylon, Polypropylene, PVC, and more |

|

Tolerance |

Tolerances can range from ±0.01 mm to ±0.05 mm |

|

Part Size |

Small components (e.g., connectors) to large parts (e.g., bumpers) |

|

Injection Pressure |

Ranges from 10,000 to 30,000 PSI depending on material and part

size |

|

Cycle Time |

Typically 15 to 60 seconds per cycle |

|

Surface Finish |

SPI grades, mirror finish, textured finishes, matte, glossy |

|

Part Complexity |

Simple to highly intricate geometries, including multi-cavity molds |

|

Production Volume |

Ideal for medium to high-volume production |

These specifications allow manufacturers to create parts that meet

precise functional and aesthetic requirements.

Applications of Plastic Injection

Molded Parts

Plastic injection molded parts are found in almost every industry. Below

are some examples of how they are applied:

1. Automotive Industry

Plastic injection molded parts are widely used in the automotive sector.

Components like dashboard parts, bumpers, interior panels,

and headlight housings are commonly made using injection molding. The

ability to produce parts with precise tolerances ensures they fit perfectly and

perform optimally.

2. Medical Devices

In the medical industry, plastic injection molded parts are

essential for creating syringes, IV connectors, surgical

instruments, and diagnostic devices. These parts must meet strict

regulatory standards for safety, sterility, and functionality. The precision of

injection molding ensures these parts are reliable in critical healthcare

applications.

3. Electronics

Plastic components are often used in mobile phones, laptops,

television sets, and computer peripherals. Injection molded parts

such as housings and connectors are designed to protect

electronic circuits and enable easy assembly of electronic devices.

4. Consumer Goods and Packaging

Plastic injection molding is a cost-effective way to produce high-quality

parts for a wide range of consumer goods, including kitchen utensils, toys,

and packaging materials. The versatility of this process allows for the

production of both small and large items with a high degree of customization.

FAQs About Plastic Injection Molded

Parts

Q1: What materials are commonly used

for plastic injection molded parts?

A: Common materials include ABS, Polycarbonate, Polypropylene,

Nylon, PVC, and Polyethylene. The choice of material

depends on the intended use of the part, including factors like strength,

flexibility, temperature resistance, and cost.

Q2: How long does the plastic

injection molding process take?

A: The time to produce plastic injection molded parts can vary. For prototype

parts, it may take several weeks, while for mass production, parts

can be produced in seconds to minutes per cycle. Production volume and

part complexity affect the timeline.

Q3: Can plastic injection molding be

used for both small and large parts?

A: Yes, plastic injection molding can be used to produce parts ranging from

small components like connectors to large parts like automotive bumpers. The

mold size and equipment used will vary based on part size.

Q4: What are the advantages of using

plastic injection molding?

A: The main advantages of plastic injection molding include high

precision, fast cycle times, low waste, and cost-effectiveness

for high-volume production. It also allows for the use of multiple materials

and the ability to create complex geometries.

Q5: Can plastic injection molded parts

be customized?

A: Yes, plastic injection molded parts can be highly customized in terms of

size, shape, color, and surface finish. Custom

molds can be designed to meet the specific needs of a product or application.

Conclusion

Plastic injection molded parts play a vital role in modern

manufacturing across various industries. The precision, versatility, and

efficiency of the injection molding process make it the go-to solution

for producing high-quality plastic components in large volumes. Whether for

automotive, medical, electronics, or consumer goods, these parts are

indispensable in creating products that are reliable, functional, and

cost-effective.

If you are looking to have plastic parts manufactured using injection molding, understanding the process, material options, and specifications is essential to ensure the quality and performance of your products.