Plastic injection Moulding company

Choosing the Right Plastic

Injection Moulding Company: A Complete Guide

In today’s highly competitive manufacturing landscape, selecting the

right plastic injection moulding company can significantly impact your

product’s quality, cost, and time to market. Whether you're a startup

developing a new product or an established brand scaling your operations,

partnering with an experienced injection moulding provider is a strategic

decision.

This blog will explore what a plastic injection moulding company does,

what to look for in a reliable partner, the technical specifications they

should meet, and answer some frequently asked questions to guide your selection

process.

What Does a Plastic Injection Moulding

Company Do?

A plastic injection moulding company specializes in manufacturing plastic

parts and components using the injection moulding process. These companies

typically offer a range of services, from product design and prototyping

to tooling, mould making, and high-volume production of plastic

parts.

Top-tier companies serve industries such as automotive, medical devices,

electronics, packaging, and consumer goods.

Key Services Offered by Plastic

Injection Moulding Companies

A full-service plastic injection moulding company provides comprehensive

support from concept to finished product:

1. Design & Engineering

Collaborative product development with DFM (Design for Manufacturability)

to optimize cost, durability, and performance.

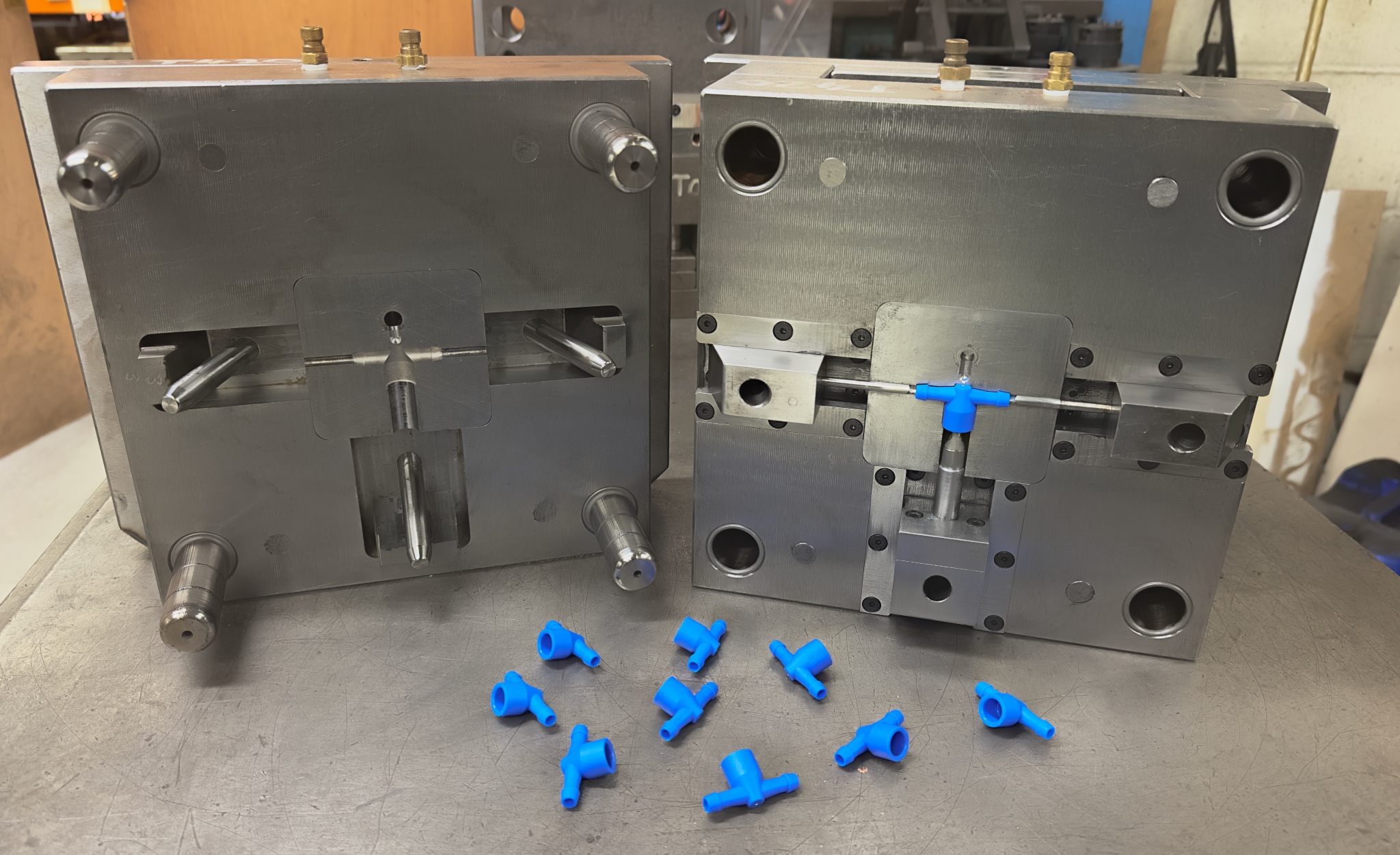

2. Tooling & Mould Making

Custom tooling services using high-quality steel or aluminum, ensuring

longevity and precision in production.

3. Injection Moulding Production

Mass production using high-tonnage injection moulding machines with

support for a wide range of materials and finishes.

4. Secondary Services

Post-moulding operations such as assembly, ultrasonic welding, surface

finishing, painting, and packaging.

5. Quality Assurance

In-house quality control, including dimensional inspection, material

verification, and ISO certifications for regulated industries.

Technical Specifications of a Leading

Injection Moulding Company

To ensure high-quality output and reliable service, a plastic injection

moulding company should meet the following specifications:

|

Specification |

Typical Range |

|

Clamping Force |

20 to 5,000 tons |

|

Injection Capacity |

1 gram to 10+ kg per shot |

|

Materials Supported |

ABS, PP, PC, Nylon, PVC, TPE, PEEK, etc. |

|

Mould Cavity Pressure |

35 – 140 MPa |

|

Tolerances |

±0.1 mm or better |

|

Surface Finishes |

Glossy, Matte, Textured, Custom |

|

Tooling Lifespan |

Up to 1 million+ cycles (steel) |

|

Certifications |

ISO 9001, ISO 13485, IATF 16949 (optional) |

These specifications highlight the capability and flexibility of an ideal

partner for projects ranging from prototype to production.

Benefits of Working With an

Established Injection Moulding Company

Choosing the right partner can unlock several key advantages:

1. Reduced Time to Market

Experienced companies streamline design, tooling, and production under

one roof, cutting lead times.

2. Cost-Efficiency at Scale

Mass production allows for lower per-unit cost and reduced material

waste, especially with optimized cycle times.

3. Access to Expert Guidance

A knowledgeable engineering team ensures your product is designed for

manufacturability, saving you from costly redesigns.

4. Superior Quality Assurance

Top moulders employ stringent quality controls, guaranteeing consistent

part dimensions and material properties.

5. Scalable Production

From low-volume runs to millions of units, experienced firms scale

efficiently with project demands.

Industries Served by Plastic Injection

Moulding Companies

Plastic injection moulding companies cater to diverse markets, including:

- Automotive – Lighting

housings, interior parts, and under-the-hood components.

- Medical – Syringes,

diagnostic devices, and surgical instruments.

- Consumer

Products – Electronics housings, furniture components, and kitchenware.

- Aerospace – Lightweight

structural and non-structural parts.

- Industrial

Equipment – Enclosures, grips, seals, and fasteners.

Their ability to meet tight tolerances and regulatory requirements makes

them essential in both high-tech and everyday product manufacturing.

How to Choose the Right Injection

Moulding Company

Here are some factors to consider when evaluating a potential partner:

1. Experience and Track Record

Look for companies with a proven history in your industry, especially if

you're dealing with regulated environments.

2. Tooling Capabilities

Ensure they have in-house or partnered tooling services with transparent

lead times and revision flexibility.

3. Quality Systems

Ask about certifications, inspection protocols, and quality assurance

equipment used.

4. Material Expertise

Your partner should understand the nuances of different thermoplastics

and help you select the right one.

5. Customer Support

A responsive and collaborative team is vital for long-term partnerships

and successful outcomes.

FAQs About Plastic Injection

Moulding Companies

Q1. How long does it take to get parts

from an injection moulding company?

A: Timelines vary based on the complexity of the part and tooling.

Typically, prototyping takes 2–4 weeks, and production runs can start in 6–8

weeks after tooling is complete.

Q2. What is the minimum order quantity

(MOQ)?

A: MOQs can range from 100 to thousands, depending on the company and

project scope. Some firms offer low-volume production for prototyping.

Q3. Can a plastic injection moulding

company help with product design?

A: Yes, many companies offer DFM support and CAD assistance to refine your

product for efficient moulding.

Q4. How much does tooling cost?

A: Tooling costs vary widely based on complexity and size—typically $5,000

to $100,000+. Some companies offer rapid tooling for lower upfront investment.

Q5. Do these companies work with

recyclable or sustainable plastics?

A: Many modern moulding companies now offer bio-based and recycled

materials to support sustainability goals.

Final Thoughts

Partnering with a capable plastic injection moulding company is a crucial

step in bringing a plastic product to life. From robust engineering support and

quality manufacturing to regulatory compliance and fast turnaround, the right

provider becomes an extension of your team.

Before signing a contract, assess their technical capabilities, customer service, and track record in your industry. A strategic partnership can save time, reduce costs, and elevate your product’s success in the market.