Plastic injection moulding process

Understanding the Plastic Injection

Moulding Process: A Complete Guide

The plastic injection moulding process is one of the most widely used

manufacturing methods for producing precise, high-volume plastic parts. From

automotive dashboards to medical device components, this process supports mass

production with exceptional repeatability and efficiency.

In this post, we’ll break down how plastic injection moulding works, its

stages, key specifications, advantages, and answer some frequently asked

questions to help you better understand the process.

What Is Plastic Injection Moulding?

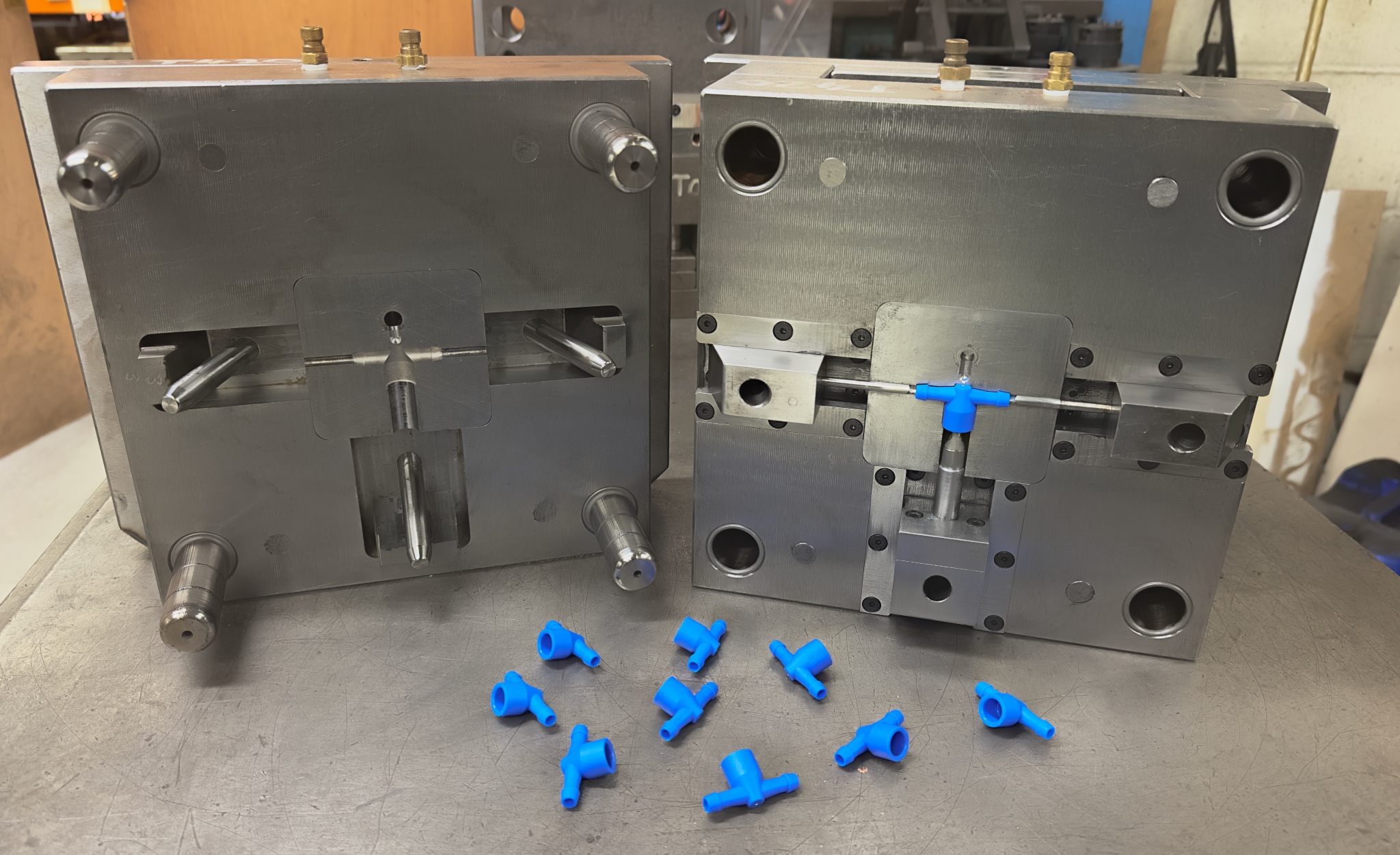

Plastic injection moulding is a manufacturing technique where molten plastic is

injected into a custom-designed mould cavity. Once cooled, the plastic

solidifies into the desired shape. The process is ideal for producing both

simple and complex plastic parts in high volumes with tight tolerances.

This method is used across industries including automotive, medical,

electronics, aerospace, packaging, and consumer goods.

How the Plastic Injection Moulding

Process Works

The process is executed in several key stages:

1. Clamping

The two halves of the mould (core and cavity) are closed and clamped

tightly using hydraulic or mechanical force. Proper clamping ensures no

material escapes during injection.

2. Injection

Plastic pellets are melted in a heated barrel and injected into the mould

at high pressure through a nozzle. The molten plastic fills the cavity

completely, taking the exact shape of the part.

3. Cooling

Once the cavity is filled, the plastic begins to cool and solidify.

Cooling time depends on the part's wall thickness, material type, and mould

design.

4. Ejection

After sufficient cooling, the mould opens, and the part is pushed out

using ejector pins. The mould then resets for the next cycle.

5. Post-Processing

Some parts may undergo trimming, inspection, or additional finishing

processes like painting, printing, or assembly.

Key Specifications of the Plastic

Injection Moulding Process

Understanding the specifications involved helps in optimizing the process

and ensuring high-quality output.

|

Specification |

Typical Range / Detail |

|

Clamping Force |

20 – 5,000 tons |

|

Injection Pressure |

30 – 200 MPa |

|

Shot Weight |

1 gram – 10+ kilograms |

|

Cycle Time |

10 – 60 seconds |

|

Tolerances |

±0.01 mm to ±0.05 mm |

|

Supported Thermoplastics |

ABS, PC, PP, PA, POM, PS, PE, TPE, PEEK |

|

Cavity Count |

Single, Multi-cavity (2, 4, 8, 16, 32+) |

|

Mould Material |

P20, H13, S136, Aluminum (prototype) |

|

Surface Finish Options |

SPI, VDI, EDM texture, mirror polish |

|

Lifespan of Mould |

100,000 to 1,000,000+ cycles |

Benefits of the Plastic Injection

Moulding Process

1. High Efficiency and Productivity

Once the mould is created, the process allows for high-speed, automated

mass production.

2. Consistent Quality

Injection moulding ensures part-to-part consistency, which is critical

for industries like automotive and healthcare.

3. Complex Geometry Capability

It supports the production of parts with intricate shapes, undercuts, and

thin walls.

4. Material Versatility

A wide range of thermoplastics, additives, and colorants can be used to

tailor part performance.

5. Reduced Waste

Compared to machining or casting, this process generates minimal material

waste, and excess can often be recycled.

Common Applications of Plastic

Injection Moulding

Plastic injection moulding is used to produce:

- Automotive

parts – interior panels, bumpers, housings.

- Medical devices – syringe

bodies, inhaler components, surgical tools.

- Electronics – connectors,

battery cases, remote housings.

- Packaging – bottle caps,

containers, dispensers.

- Consumer

products – kitchenware, toys, household gadgets.

Each application may require different tooling, materials, and processing

conditions, all of which must be optimized.

Factors That Influence Injection

Moulding Success

To ensure an effective production process, consider the following:

1. Mould Design

A poorly designed mould can cause defects like warping, sink marks, or

short shots. Proper venting, gating, and cooling must be engineered.

2. Material Selection

Not all plastics behave the same. Properties such as melt flow,

shrinkage, and temperature resistance must match the application.

3. Machine Parameters

Pressure, temperature, injection speed, and cycle time must be carefully

monitored and controlled.

4. Part Design

Designing for manufacturability includes adding draft angles, uniform

wall thickness, and ribbing for strength without overuse of material.

FAQs About the Plastic Injection

Moulding Process

Q1: What is the average cycle time in

injection moulding?

A: Most parts have a cycle time of 15 to 60 seconds, depending on size,

complexity, and material used.

Q2: What are the most commonly used

plastics in injection moulding?

A: Popular materials include ABS, polypropylene (PP), polycarbonate (PC),

nylon (PA), polyethylene (PE), and thermoplastic elastomers (TPE).

Q3: How long does a mould typically

last?

A: A well-maintained steel mould can last for 500,000 to over 1,000,000

cycles, while prototype aluminum moulds may last for 10,000 to 100,000 cycles.

Q4: Can injection moulding be used for

low-volume production?

A: Yes, especially with aluminum tooling or insert moulding. However, it’s

most cost-effective for medium to high-volume runs.

Q5: What are common defects in

injection moulding and how are they prevented?

A: Common defects include warping, sink marks, flashing, and short shots.

Proper mould design, material selection, and process control are key to

prevention.

Final Thoughts

The plastic injection moulding process is a cornerstone of modern

manufacturing due to its speed, accuracy, and ability to produce parts at

scale. From idea to final part, each step—from design and material selection to

mould making and production—must be executed with precision.

If you’re planning to develop a plastic product or scale production, understanding this process is essential. Choosing the right mould, the appropriate material, and a qualified manufacturing partner will directly impact your success in cost, quality, and lead time.