Plastic mold manufacturers

Plastic Mold Manufacturer: A Complete Guide to

Choosing the Right Partner

When it comes to manufacturing plastic components with high precision and

efficiency, the role of a plastic mold manufacturer is indispensable.

These companies specialize in designing and producing custom molds that shape

raw plastic into functional parts used across industries such as automotive,

medical, consumer goods, and electronics.

In this blog post, we’ll explore what plastic mold manufacturers do, what

services they offer, key technical specifications, and how to choose the right

one. We’ll also answer frequently asked questions to help guide your

decision-making process.

What Does a Plastic Mold Manufacturer

Do?

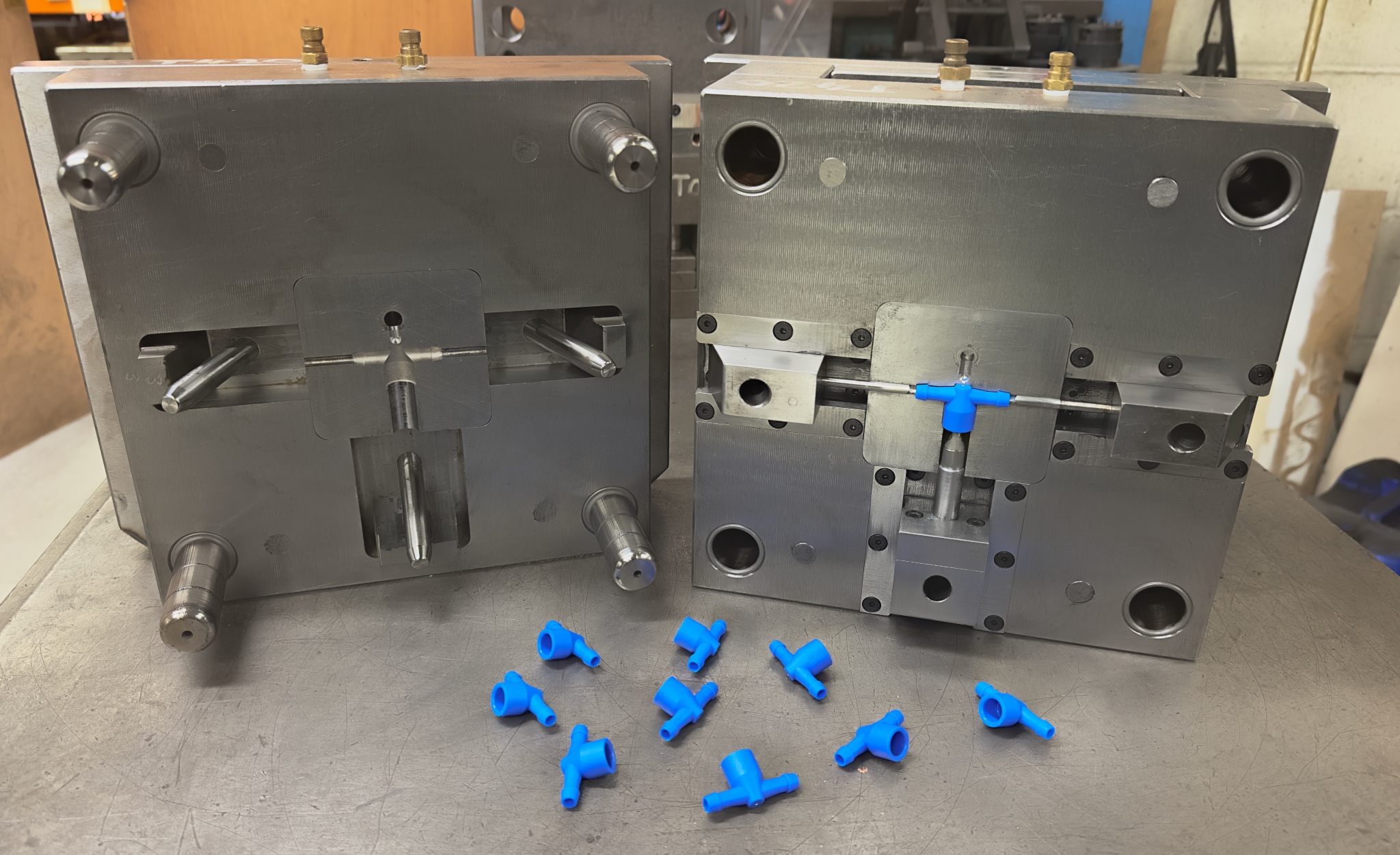

A plastic mold manufacturer is responsible for the design,

fabrication, testing, and maintenance of molds used in plastic injection

molding, blow molding, compression molding, or other plastic forming processes.

These molds are the critical tools that define the geometry, texture, and

structural features of the final product.

Plastic mold manufacturers typically work closely with product designers,

engineers, and injection molding companies to ensure the molds meet technical

requirements, production volume expectations, and cost targets.

Core Services Offered by Plastic Mold

Manufacturers

A reliable plastic mold manufacturer offers a full range of services to

support both prototyping and full-scale production:

1. Mold Design and Engineering

Using advanced CAD and simulation tools, engineers design the mold based

on part geometry, material type, and production needs.

2. Tooling Fabrication

High-precision machining technologies such as CNC milling, EDM

(electrical discharge machining), and surface grinding are used to produce

complex mold components.

3. Prototype Molding

Manufacturers may create soft (aluminum) or rapid prototype molds for

testing part fit, form, and function before committing to full-scale

production.

4. Mold Testing and Validation

Trial runs and sample production are conducted to verify part quality,

proper cooling, and ejection performance.

5. Mold Maintenance and Repair

After delivery, ongoing maintenance services are provided to extend the

mold’s life and ensure consistent performance over time.

Specifications to Expect from a

Quality Plastic Mold Manufacturer

Here are key technical specifications and features to consider when

evaluating a mold manufacturer:

|

Specification |

Standard or Range |

|

Mold Base Material |

Steel (P20, H13, S136), Aluminum |

|

Mold Life Expectancy |

100,000 to over 1,000,000 cycles |

|

Cavity Number |

Single, 2, 4, 8, 16, 32+ cavities |

|

Tolerances Achievable |

±0.01 mm to ±0.05 mm |

|

Surface Finish Options |

SPI A1–D3, EDM texture, VDI, mirror polish |

|

Supported Plastics |

ABS, PC, PP, PE, TPE, Nylon, POM, PEEK, etc. |

|

Cooling System |

Conventional or conformal cooling channels |

|

Hot/Cold Runner Options |

Hot runner, cold runner, valve gates |

|

CAD/CAM Software Used |

SolidWorks, Siemens NX, CATIA, AutoCAD, Moldflow |

|

Certification Options |

ISO 9001, ISO 13485 (medical), IATF 16949 (automotive) |

Industries Served by Plastic Mold

Manufacturers

Plastic mold manufacturers cater to a wide variety of industries that

demand durable, high-precision plastic parts:

- Automotive – Interior

panels, lighting housings, and under-hood parts.

- Medical – Syringes,

diagnostic device housings, and surgical instruments.

- Consumer Goods – Packaging,

kitchen tools, toys, and electronics casings.

- Electronics – Connectors,

smartphone cases, switch housings.

- Aerospace &

Defense – Lightweight components, enclosures, and support structures.

Each industry may have unique regulatory or tolerance requirements, so

selecting a manufacturer with domain expertise is vital.

How to Choose the Right Plastic Mold

Manufacturer

Selecting the right manufacturing partner involves evaluating technical,

operational, and customer service capabilities. Here are the most important

factors to consider:

1. Experience and Industry Knowledge

Choose a company with proven experience in your specific industry or

similar product types.

2. In-House Capabilities

Ensure the manufacturer can handle the entire mold-making process

internally—from design to validation.

3. Material Knowledge

The right manufacturer will recommend the best materials for your

application, considering durability, mold life, and cost.

4. Certifications and Quality

Standards

ISO or industry-specific certifications demonstrate a commitment to

quality and compliance.

5. Post-Delivery Support

Maintenance, rework, and after-sales support are critical to the

long-term performance of your mold investment.

FAQs About Plastic Mold

Manufacturers

Q1: How long does it take to

manufacture a mold?

A: The lead time for mold manufacturing typically ranges from 4 to 12 weeks

depending on complexity, number of cavities, and revisions.

Q2: Can a mold be reused for different

parts?

A: No, each mold is custom-made for a specific part geometry. Modifying an

existing mold is possible but often expensive and time-consuming.

Q3: What is the difference between

prototype and production molds?

A: Prototype molds (usually aluminum) are used for short runs and testing,

while production molds (usually steel) are durable and built for high-volume

manufacturing.

Q4: What materials can a plastic mold

work with?

A: A quality plastic mold can be designed to handle a wide range of

thermoplastics, including ABS, polycarbonate, polyethylene, polypropylene,

nylon, and more.

Q5: Do plastic mold manufacturers

offer global shipping and support?

A: Many reputable manufacturers offer international service and global

logistics support. However, local support or partnerships in your region can

improve turnaround times and communication.

Final Thoughts

Working with a trusted plastic mold manufacturer is a vital part

of any product development and production process. Whether you're launching a

new consumer product or producing high-volume automotive parts, the quality and

reliability of your mold will directly impact your production efficiency, product

quality, and bottom line.